Cooling towers are frequent choices for vibration monitoring due to their often-critical role in maintaining operational efficiencies. Vibration analysis can be used to improve reliability and extend the lifetime of cooling tower equipment. While cooling towers range from small single-cell units to large multi-cell configurations, any configuration that employs the use of rotating parts requires effective monitoring.

How It Works

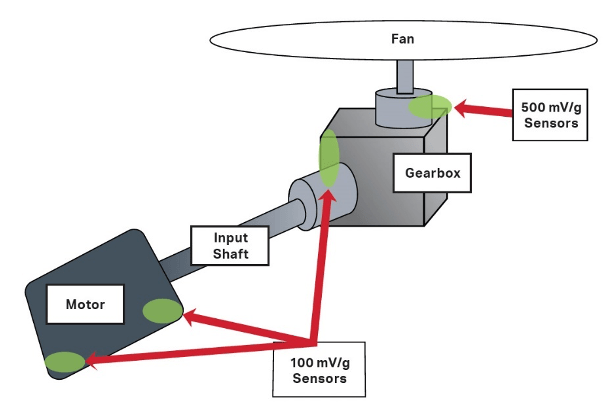

The machinery generally consists of three phases: motor, gearbox, and fan. In order to provide maximum reliability, all three phases should be monitored. To accomplish this, accelerometers should be placed at key places on the motor, gearbox, and fan bearings. Typically, vibration sensors are mounted on the bearing surface in either the horizontal, vertical, or axial directions.

What CTC Offer

Accelerometers:

For maximum coverage, six sensors should be used on both the motor and gearbox for a total of 12 sensors per installation.

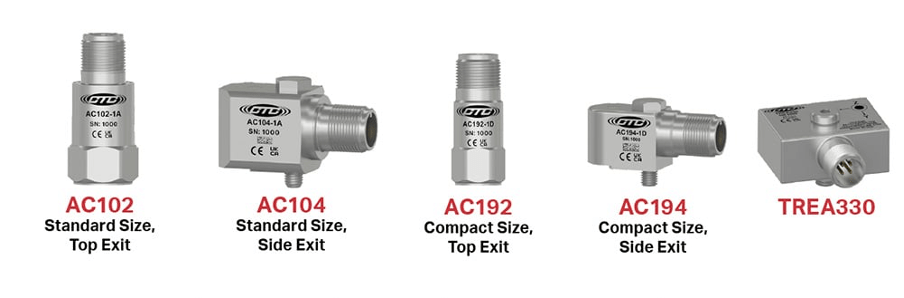

General-purpose sensors like CTC’s AC102, AC104, AC192, AC194, and TREA330 series sensors rated at 100 mV/g would be recommended for applications over 30 CPM (0.5 Hz):

Low-frequency applications from 6 CPM to 30 CPM (0.1 to 0.5 Hz) should use a 500 mV/g sensor like CTC’s AC133, AC134 or TXFA331 series accelerometers:

Cables and Connectors:

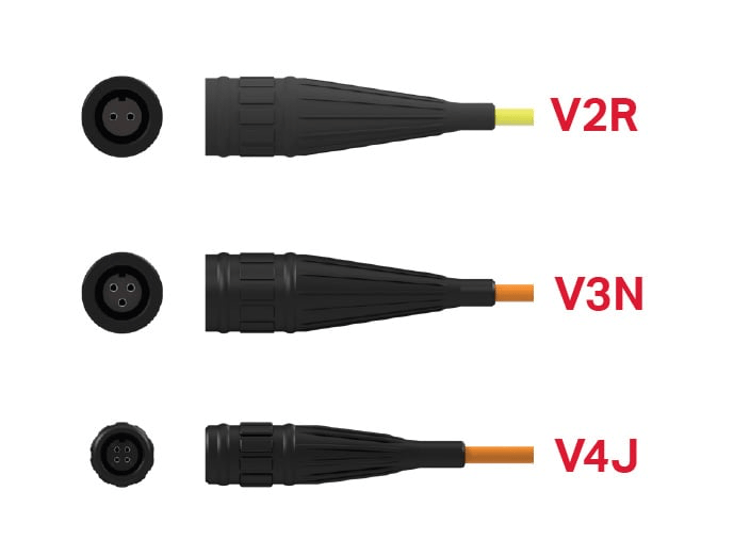

CTC’s V Series Viton® Boot Connectors are ideal for use in the wet, caustic environment created by cooling towers. They create an IP68-rated seal with the sensor and are excellent in highly-corrosive environments. CTC recommends using these connectors in conjunction with CTC’s CB111 or CB119 FEP jacketed cables.

V Series connectors (V2R, V3N, and V4J) come in 2, 3, and 4-pin options for use with single-axis, biaxial, or triaxial sensors.

These cables should be connected to a switch box such as the JB110, which is also capable of passing the signal through to a remote monitoring system such as a DCS, PLC, or SCADA System: